Installation Ring and Modular Housing Concept

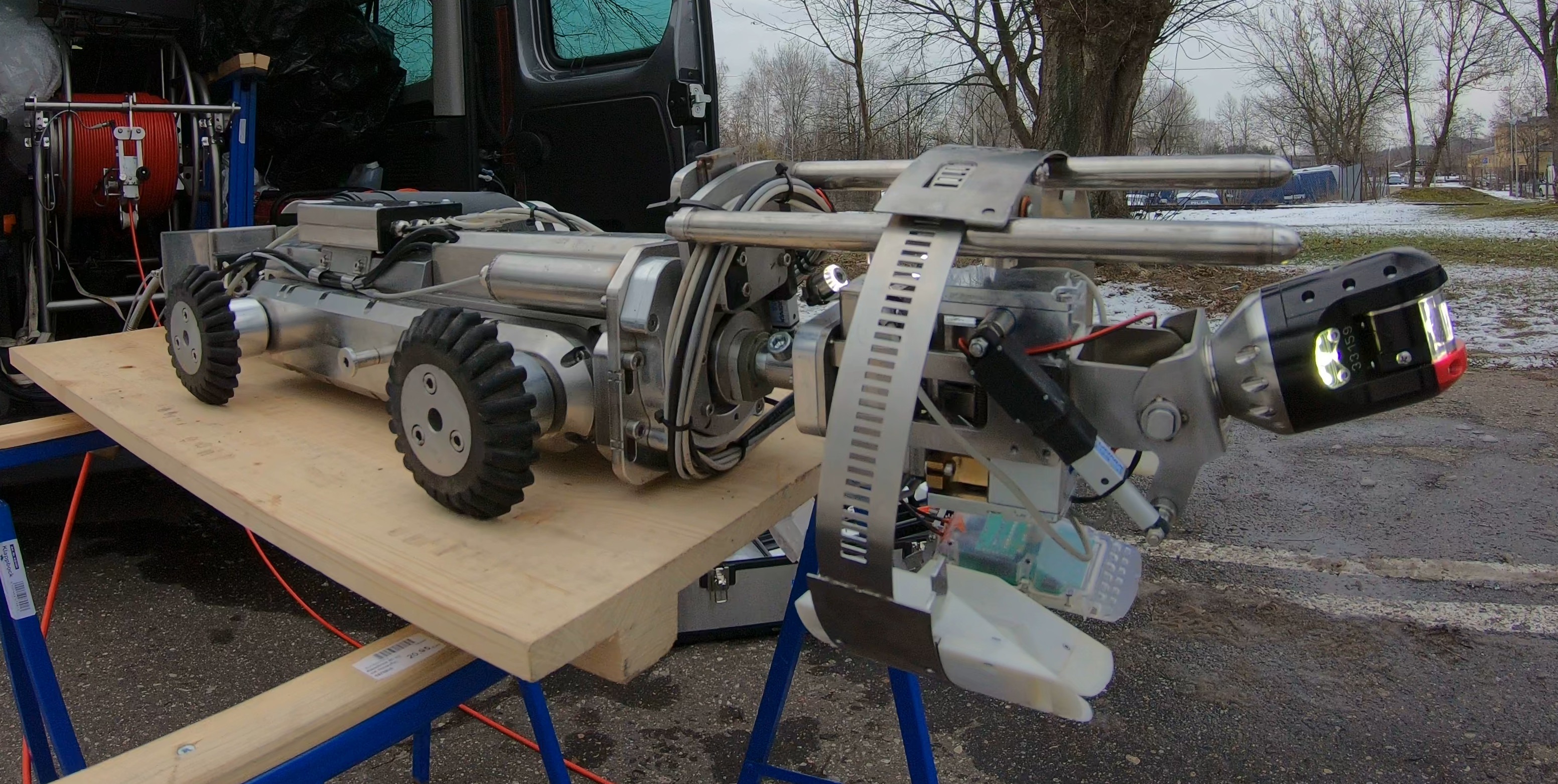

Crawler Robot.

A crawler robot and tool along with adjustable sleeves, cable drum and remote control was developed, manufactured and tested under lab and real conditions. Assembly and disassembly of sensor rings were demonstrated successfully.

The working tool of the robot has ten axes of movement, three cameras in fixed positions and one pan-tilt front camera with 350° vision. Remote control by CAN bus allows the use of thin cables, which lead a max. working distance of 500m. The adjustable sleeve concept allows a robust fixation of micromole rings in sewage. A patent for that concept is pending

Housing and Integration.

A modular housing concept for electronics and fluidics was developed, which enables the micromole team to integrate varying modules in the micromole sensor system and to allow the sensing device placing within sewage, while not interfering with the normal wastewater flow. The housing is water tight and resistant to acids, solvents and temperatures till 60 °C. A miniaturized, watertight 16-pole connector was developed.

Hardware and Software Design.

A sensing platform for pH and electrical conductivity measurements in harsh environments was developed. Suitable sensing elements (pH and EC) were selected and successfully integrated into a housing which does not restrict the waste water flow and rarely get clogged. The developed electronics of the sensing module are properly designed to work with the chosen sensing elements to achieve the specified behaviour (response time, resolution, accuracy). Multiple tests in artificial and real sewage systems were conducted (after different development states) to evaluate the performance of the sensing modules and to make sure the system meets the specifications.

System Reliability Assurance.

A workflow for quality and reliability assurance was developed and deployed among project partners. Together with colleagues from UniBWM, BKA and CFLP fourteen test sessions were prepared and accompanied.

Interdisciplinary research projects that are starting with low and varying TRL levels and are aiming at a high TRL level fall often at the point when the different work packages should be integrated. Due to the nature of research, failures will occur at this point. By high dependencies among the results, a failure of one module cause the failure of the system. Consequently, the other project partners cannot test their parts with all consequences in time and quality.

Test levels were defined with regard to the application (home lab, sewage lab, real sewage). The micromole system was sub classified in hierarchical (functional) layers. Tests and test level per layer were defined. Testing started at the lowest level. A prerequisite for a step up in a hierarchical layer was a successful test. In addition, test plans with checklist and recommended test sequences were developed.

Due to the harsh conditions of using electronics inside the sewage system, information about moisture diffusion are of key importance for obtaining reliable systems. Results from numerical simulations brought new insides in moisture diffusion in housing material.